OFFLINE CLEANING SYSTEM

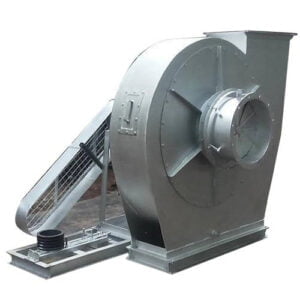

Pulse Jet Bag Filter

An offline cleaning pulse jet bag filter consists of a number of chambers. Each chamber acts similar like online pulse jet bag filter. The uniqueness of the design is in the fact that the supply of inlet gas to the chamber is stopped during cleaning temporarily. Dust falls into the hopper after the bags are purge with compressed air, since there are no incoming gases into the chamber the dust collection is faster. Dust is evacuated using a rotary airlock valve. Remaining chambers continue to remain in operation and continue the filtration process. One after the other each chamber is made offline for cleaning & the process continues in cycles.

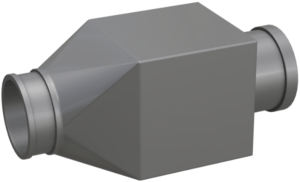

Our Offline Cleaning System

Off-line cleaning of the bag filter requires that the dust collector be designed as a multi-chamber combination to achieve chamber-by-room cleaning. When a filter room needs cleaning, the filter room is isolated from the main air flow. The filter room is isolated by setting the inlet or outlet valve is implemented. This process is maintained for about 2 to 3 minutes. As a result, the total filter area (or called the gross filter area) of the precipitator during each cleaning operation is reduced by the area of the filter cloth in one chamber, and the reduction in the total filtration area also results in an effective filtration area (or net filtration area).

A B ENTERPRISE supply Their products all over India specially in West Bengal & Kolkata, Jharkhand, Chhattisgarh, Bihar, Odisha, Cuttack, Bhubaneswar, Uttar Pradesh, Tamilnadu, Karnataka, Meghalaya, Andhra Pradesh, Punjab, Assam and so on.

Click Here to Download Our Product Brochure