ONLINE CLEANING SYSTEM

PULSE JET BAG FILTER

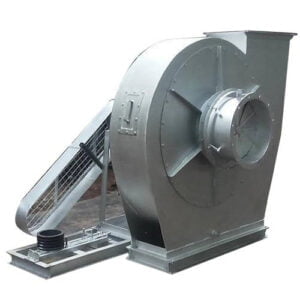

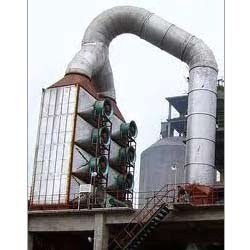

We A B Enterprise is a leading manufacturer of Industrial Dust Collection System specially Pulse Jet Bag Filter. Bag filter dust collector are used for the clarification/filtration of fluids that have a relatively small loading of particles to be removed. A Baghouse, also known as a Baghouse filter, bag filter, or fabric filter is an air pollution control device and dust collector that removes particulates or gas released from commercial processes out of the air. A Fume Extraction System is a system utilizing a fan to pull fumes and particulate into a filtration system cleaning the air of harmful chemicals and particulates.

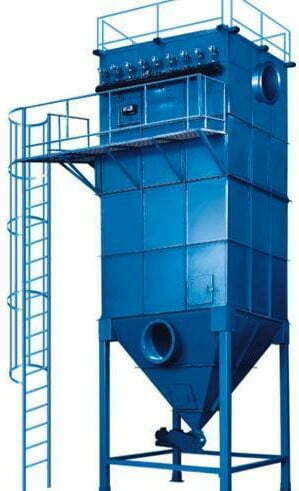

Online Cleaned Pulse Jet Bag Filter is one of the most efficient and commonly used Bag Filter. Consists of the capsule at the top with bag mounting arrangement housed in the casing. The hopper is place under this and connected to a dust evacuation system like the rotary airlock valve.

The entire system is supported on columns or stools depending upon plant location. Dust laden gas enters the hopper and passing the filter bags. The filtration elements collect the dust and drop it into the hopper below. Clean gas is released through the opening in the capsule. So, In order to dislodge the dust, an automated sequential cleaning system is employed. This purges compressed air at high pressure after regular intervals. We design Pulse Jet Bag Filter as per client requirement and design.

Transfer of material over belt conveyors often involves transfer points. There the dust is drop from one point to the other. Venting on top of bins / hoppers / silos calls for a design which is customized for that particular application. Specifically for such applications a flush mounted Bag Filter is designed which is devoid of a hopper, support structure and dust evacuation system. Casing is directly mounted on top of the venting point, dust collected through the opening is dropped into the system below i. E. Directly into the silo / hopper / bin or onto the conveying belt below.

OUR ONLINE CLEANING SYSTEM

Firstly, High-pressure pulsed air is ejected at high speed from the pulsed electromagnetic valve through the gas pipeline from the injection hole above the center of the filter bag, passing through the neck of the Venturi tube above the filter bag, including the induced secondary air, and rushing towards the inside of the filter bag along the way a short impulse pressure wave is generated in the longitudinal direction of the filter bag, and Therefore the dust deposited on the surface of the filter bag is peeled off. After that the dust falls into the ash bucket.

The clean gas is evacuated through the purifying chamber. When the solenoid valve is de-energized, the pulsed solenoid valve diaphragm closes and stops the high-pressure pulsed air flow, and the end of a cleaning operation is completed.

A B ENTERPRISE supply their products all over India specially in West Bengal & Kolkata, Jharkhand, Chhattisgarh, Bihar, Odisha, Cuttack, Bhubaneswar, Uttar Pradesh, Tamilnadu, Karnataka, Meghalaya, Andhra Pradesh, Punjab, Assam and so on.

Click Here to Download Our Product Brochure